Injuction Molding facilities & Assembling

- The plastic injection moulding process produces large numbers of parts of high quality with great accuracy, very quickly.

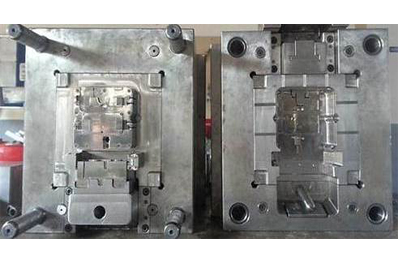

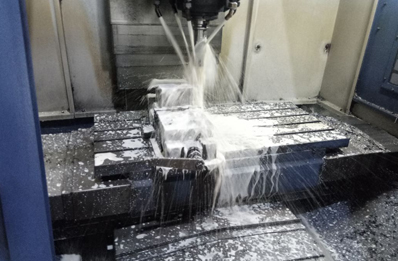

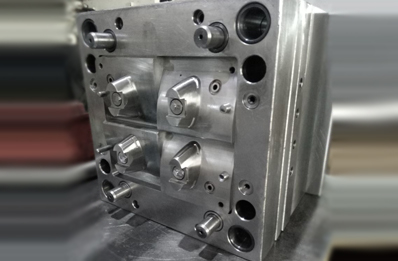

- Tool design & manufacturing capabilities of the group are a key to its ability to provide full system solutions.The tool rooms specialize in high precision, multi cavity, small, medium and large size tools capable of running on injection molding machines upto 1000 tonnes.

- Plastic material in the form of granules is melted until soft enough to be injected under pressure to fill a plastic injection mould. The result is that the shape is exactly copied. Once the plastic moulding has cooled sufficiently to harden the mould opens releasing the part. The whole injection moulding process then repeats.